Verification testing of an implantable medical device

Client: Confidential

Description: Creating a test to verify that a medical implant could last 10 years in the body without leaking, in order to pass regulatory controls and ultimately launch it to market.

Activities: Usability evaluation studies, Mechanical design, prototyping, rendering, testing and evaluation

Developing the test

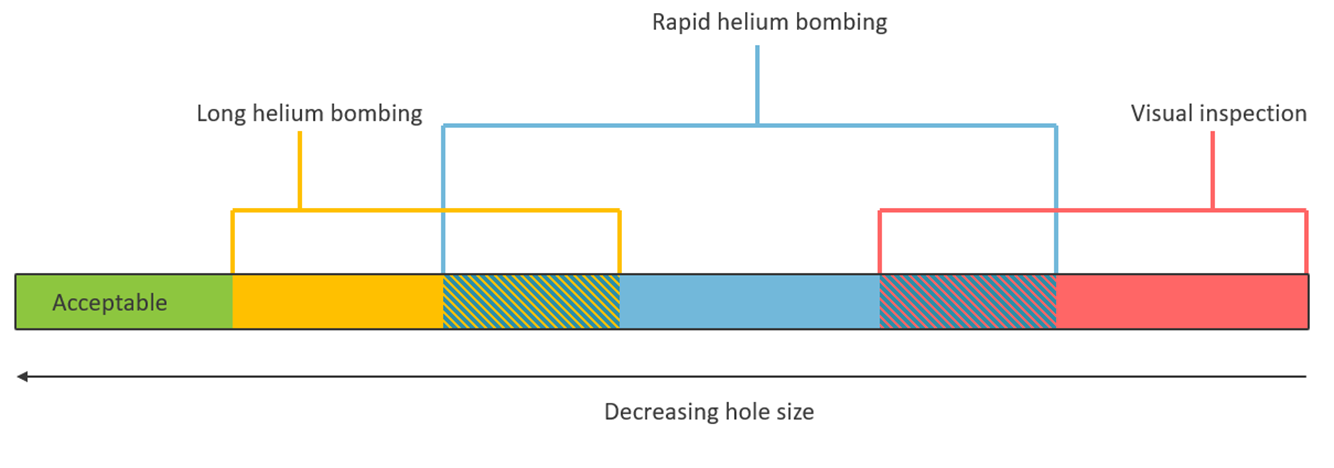

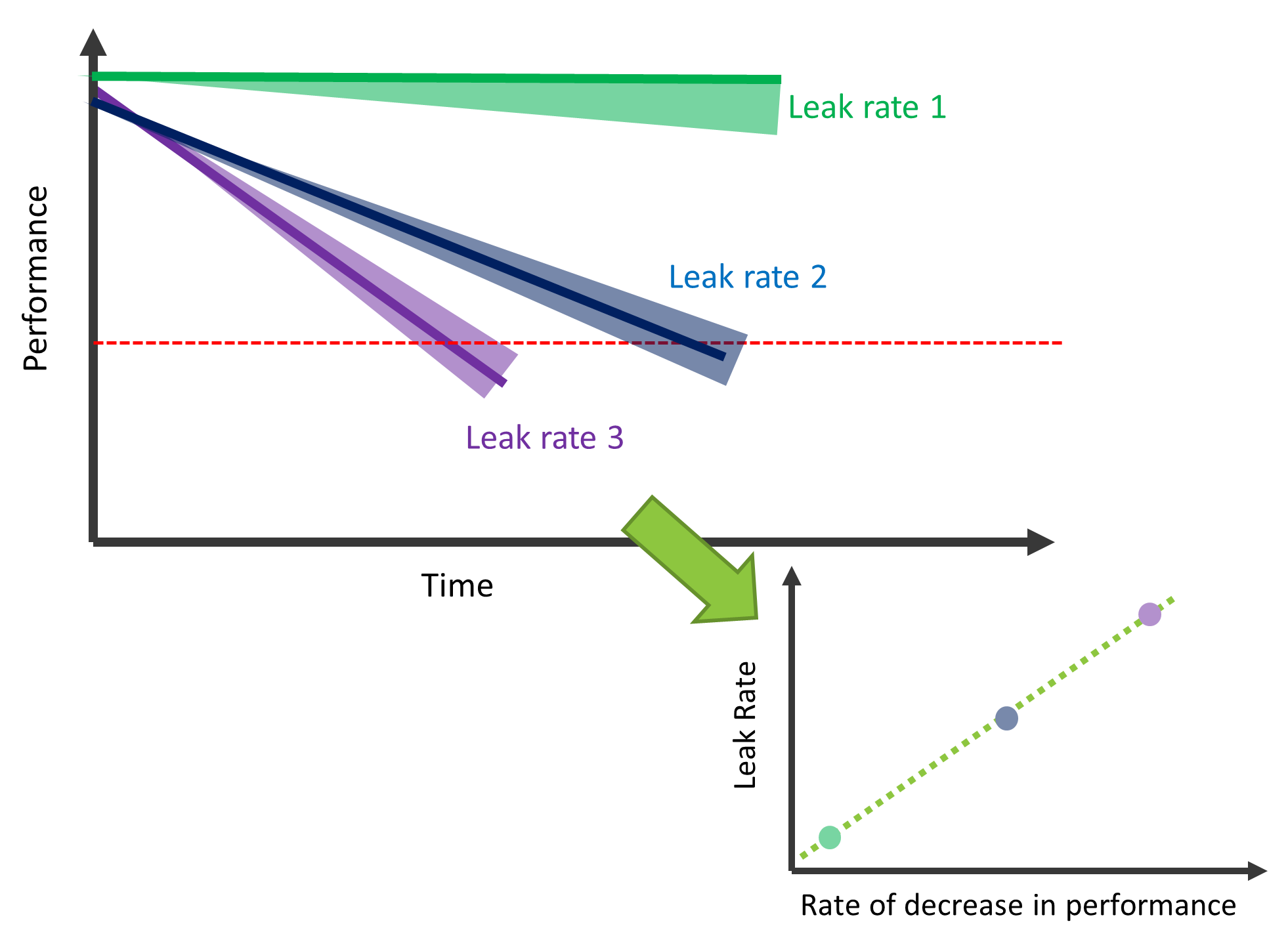

We developed a three stage test to inspect for leaks. Stage 1 was a visual inspection. Stage 2 used the rapid helium bombing method to catch large leaks and finally stage 3 involved a long helium bombing process whereby any small leaks were detected.

We tested the protocol with known leaky samples and edge cases to ensure that the test method produced valid results across a representative range of parts. Once we had confidence in the test method we proceeded to design verification and validation, and subsequently our clients could launch the product.

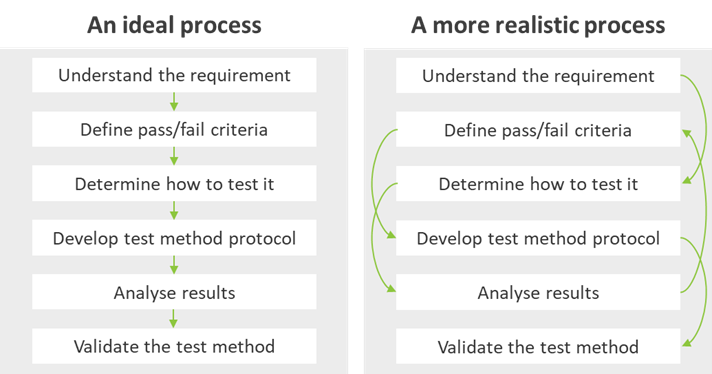

Developing verification tests can be more complex than first envisioned. It is important to have a detailed technical understanding of the requirements and product to ensure that verification methods and acceptance criteria reliably prove the safety and effectiveness of the product. For novel designs, it can be necessary to think creatively about the most valuable methods of verification and to create bespoke test protocols.