Our Process

We employ PhD and Master’s level scientists with experience across a range of disciplines including bio-engineering, materials science and physics.

Our approach to science is underpinned by focussed research, theoretical analysis and physical testing.

Measure

The first step in understanding is to measure the system and the operating conditions. The team at Springboard are skilled at obtaining high quality experimental data. Our experienced scientists have designed bespoke experiments for extreme temperature, in small spaces, under high forces and in many more challenging situations.

Analyse

The next step is to analyse the data and relate it to theoretical principles. We have experience in statistical analysis, curve fitting, Monte Carlo simulation, numerical modelling and finite element analysis. Our approach is generally very practical but it is important to use scientific theory to guide the measurements.

Understand

Once we have an experimentally validated description of the system then we can use this to drive improvements or solve problems. Springboard develops products right through to manufacture so the understanding developed by scientists in the early stages of development is used in later product development to ensure efficient and robust design.

Key competencies

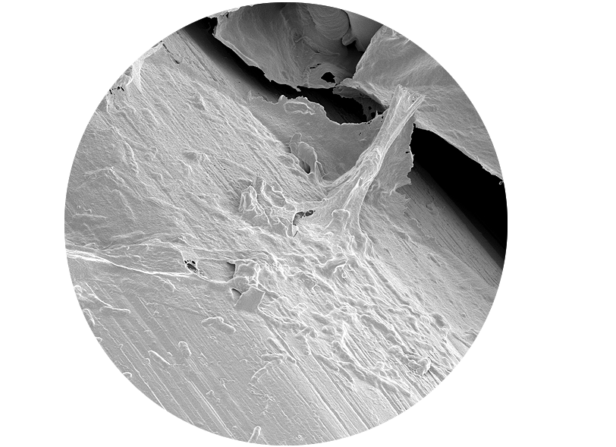

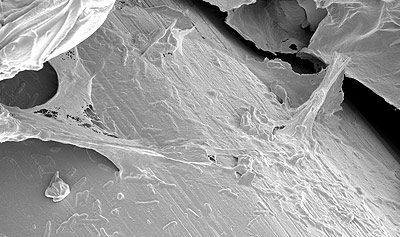

Materials science

Our team has in-house expertise in materials science: from metals and alloys to ceramics, polymers and beyond. Understanding the physical and chemical properties of these materials allows us to model their behaviour and potential failure modes.

We have experience in: imaging using optical and electron microscopy; measurement of mechanical properties; measurement of thermomechanical properties of polymers; characterisation of functional materials; and the analysis of corrosion and degradation processes.

Key applications include mechanical failure analysis and lifetime prediction, as well as selection of appropriate materials to meet design requirements.

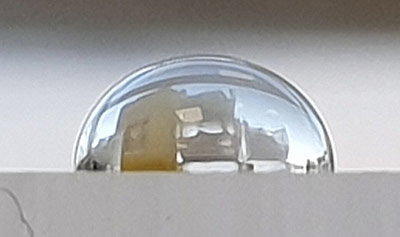

Surface chemistry and interfaces

Many devices rely on the behaviours of surfaces and interfaces. Understanding chemical and physical processes occurring on these surfaces, such as friction, adsorption, wetting, nucleation and biochemical processes, allows us to tune and optimise their behaviours. On top of our in-house competencies, we interact regularly with external laboratories and partners, giving us access to an extensive suite of characterisation techniques.

Key applications include device mechanisms, filtration processes, syringes, chemical compatibility and adhesive bonding.

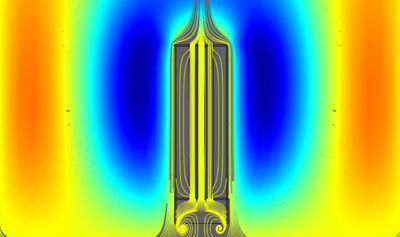

Fluids and thermodynamics

The ability to control the transport of fluids and heat is often critical to the function of a device. We have experience in designing and visualising flow paths for liquids and gases, measuring fluxes and pressures, controlling humidity, analytical calculations and CFD simulations. We have also designed devices which require temperature stability or have heat sources. We have used advanced thermal management techniques including heat pipes and heat plates to remove heat or efficiently transfer it through the device.

Applications we have worked on include moisture vapour transmission, radiative heaters and catalytic burners.

Cryogenics and electromagnetics

We have specialist knowledge of material and system behaviours at cryogenic temperatures down to liquid helium temperatures. We have experience in low temperature thermometry, vacuum systems, thermal insulation, phase diagrams and phase changes. Our team has handled cryogenic liquids and designed devices which can operate at these extreme temperatures.

We also have advanced capabilities in magnetism, specifically susceptibility measurements, magnetic field calculations, Hall Effect measurements and stress calculations. Applications range from cryo-surgical devices to superconducting magnets.

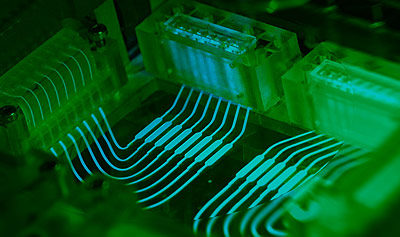

Microfluidics and lab on chip

We have a broad range of experience in microfluidic systems which includes modelling of thermal and fluidic systems as well as the dynamics of chemical reactions and ion transport. We have extensive knowledge of microlithographic fabrication, prototyping of microfluidic chips, layer bonding and custom sensor integration.

Applications include nebulisation as well as therapeutic, diagnostic, and lab-on-chip devices for gene sequencing and cell sorting.

Biomedical engineering and biophysics

Our biomedical engineering experience spans regenerative medicine, bio-interfaces and the industrial manufacture of biologics. We have key skills in cell processing, tissue engineering and biomaterials. This includes fabrication of hydrogel scaffolds, bioactive surfaces, differentiation of stem cells into functional organelles and the analysis of metabolites and signalling molecules. We have also worked on numerous implantable devices and systems for up- and downstream processing of cells and biopharmaceuticals.

Applications range from organ-on-chip to biosensors, bioreactors and implanted devices.

Lasers, optics and semiconductors

We have developed laser scattering and imaging systems, both at the benchtop scale and integrated into electronic scanning products. This includes geometric optics design, anti-reflection coatings and ray tracing. We have experience of generation and spectroscopy in the terahertz, visible and infrared wavelengths, and can also advise on the development of semiconductor physics and fabrication processes.

We also cover real-time data collection and processing, using both hardware and software, which is closely related to many projects in these areas.

Applications range from Schlieren photography to measure convection currents in air, through to laser machining of microdevices for the medical industry.

Acoustics and vibration

We have a wide range of skills in acoustics and ultrasonics. We have modelled the interaction of ultrasonic waves passing through layers of composite media and can evaluate resonances in devices, find the source of vibrations and reduce unwanted noise with help from our acoustic analysis equipment. In one project, the audible spectrum of a medical device was analysed, traced to a particular component, and then engineered to eliminate the sound.

This skill set can also be applied to piezoelectric oscillators, droplet generators, and ultrasonic technology.