CDMOs as a Strategic Enabler for Device Industrialisation

9 July 2025

The medical device industry is larger and more innovative than ever. Clinical research is experiencing a surge of innovation in…

Mind the Gap

11 June 2025

Closing the Gaps in Drug Delivery Development Developing drug delivery devices is rarely straightforward. While there are a variety of…

The Rise of the Next-Gen CDMO: Strategies for Reducing Risk and Time to Market

16 October 2024

By Alex Vasiev, Head of Biointerface, Springboard Creating and producing advanced drug-device combinations, like autoinjectors and pen injectors, requires a…

6 essential steps of forensic medical device engineering

7 May 2024

Written by Thom Wyatt, Principal Engineer Forensic medical device engineering is a high-stakes discipline, where experts investigate and analyse medical…

R&D project support for startups

3 May 2024

For startups, research and development (R&D) is a crucial part of building your product. Here you can explore and develop…

Unravelling complexities: How forensic engineering enhances device development

1 May 2024

In technological innovation, the journey from concept to market-ready device is often fraught with challenges and uncertainties. From intricate mechanical…

Springboard Pro to Host Networking Event for Startups in the Medical Device and Diagnostic Sphere

24 April 2024

Springboard Pro, a leading engineering consultancy, is pleased to announce its upcoming networking event tailored specifically for startups operating in…

Start up Grant Aims to Support Medical Device Industry Innovation

26 March 2024

Springboard Pro proudly announces the launch of its 2024 Start-up Grant. This program is specifically tailored to assist fledgling medical…

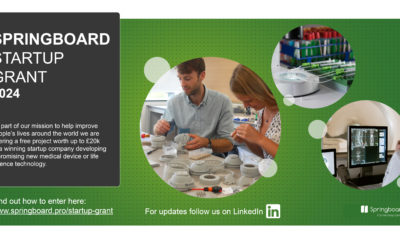

Lab-On-Chip Devices: Materials Considerations

18 March 2024

Material selection and testing can often be one of the critical challenges to developing microfluidic devices for the healthcare and…