Transfer to manufacture: selecting a partner

1 February 2023

It is a nightmare scenario: you have a great product and commercial opportunity, but you are going to be late…

Top five tips for sustainable device design

10 October 2022

Following COP26, device manufacturers are facing increasing pressure both from government and from consumers to reduce the environmental impact of…

Challenges in developing lab-on-a-chip devices

1 March 2022

Lab-on-a-chip (LOAC) devices are miniaturised systems that process or test small volumes of liquid. Efforts to develop such devices are…

Springboard offers medical device expertise to tackle COVID-19

24 March 2020

One of Springboard’s three motivations is to help peoples’ lives around the world. The current pandemic of COVID-19 is concerning…

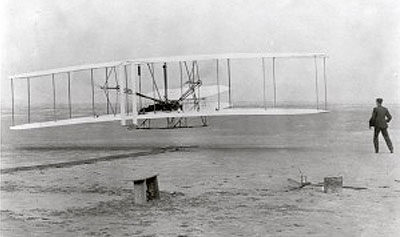

Strategies for faster R&D: Change one variable at a time

27 June 2019

When the Wright brothers were trying to make their great aeronautical leap forward, they didn’t just throw feathers and…

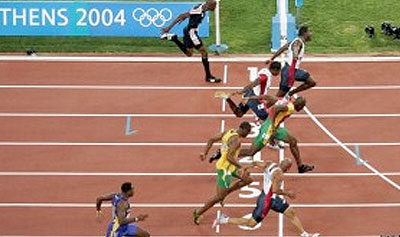

Strategies for faster R&D: High speed video

20 June 2019

When the world’s fastest men competed for the 100m Olympic gold medal in Athens, 2004, four athletes crossed the line…

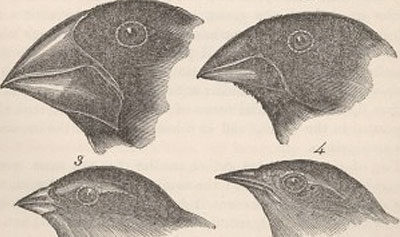

Strategies for faster R&D: Critical Observation

7 June 2019

Nearly 200 years after its inception, Darwin’s theory of evolution still lives as one of science’s greatest breakthroughs. Yet Darwin…

3 sure steps to faster R&D

21 September 2018

Are you an R&D manager who would like to get your products to market more quickly? You may have suffered…

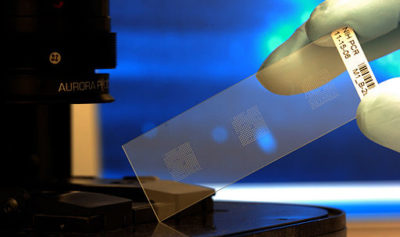

Nanopatterning for medical applications

6 September 2018

Nanotechnology appears in popular culture as a cure for everything from cancer to balding. In science nanotechnology is an umbrella…