Superficial attraction: better membranes through surface science

6 March 2024

The importance of understanding surface properties Water is a multifaceted actor in our lives, being variously an ingredient in food,…

Strategies for faster R&D: Change one variable at a time

27 June 2019

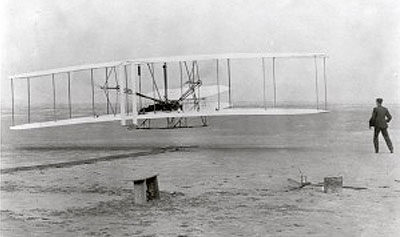

When the Wright brothers were trying to make their great aeronautical leap forward, they didn’t just throw feathers and…

Strategies for faster R&D: High speed video

20 June 2019

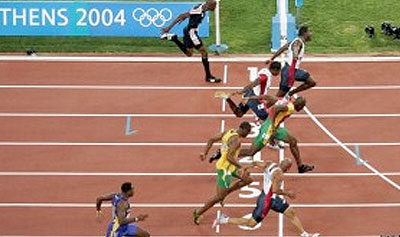

When the world’s fastest men competed for the 100m Olympic gold medal in Athens, 2004, four athletes crossed the line…

Strategies for faster R&D: Critical Observation

7 June 2019

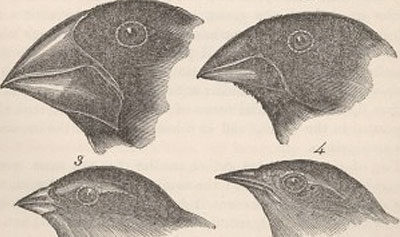

Nearly 200 years after its inception, Darwin’s theory of evolution still lives as one of science’s greatest breakthroughs. Yet Darwin…

Strategies for faster R&D

10 October 2018

Could you really cut R&D times by a factor of five? Senior R&D managers are constantly under pressure to deliver…

3 sure steps to faster R&D

21 September 2018

Are you an R&D manager who would like to get your products to market more quickly? You may have suffered…

Springboard’s primary school partner gains national science award

18 December 2017

Springboard believes in inspiring the next generation of scientists and so engages in outreach activities at all ages. For the…

Careers evening in Cambridge 9th Feb 2017

3 February 2017

Join us at The Cambridge Brew House on Thursday 9th February from 18:30 – 20:30 to find out more about…

Strategies for faster R&D: Break it into manageable steps

3 February 2017

When Edmund Hillary and Tenzing Norgay climbed Everest for the first time in 1953, they didn’t just take a giant…