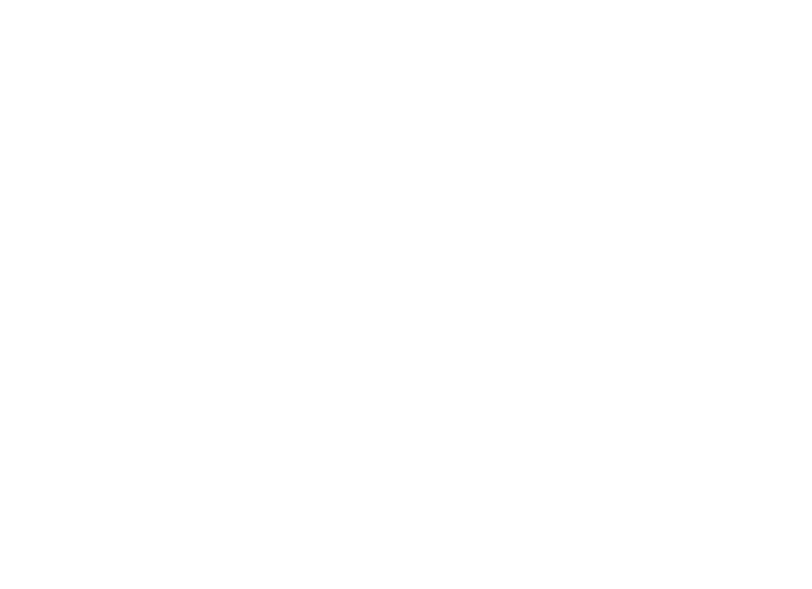

Capacity is the new capability: Meeting market demand

4 December 2024

At the recent PDA Universe of Prefilled Syringes and Injection Devices conference in Phoenix Arizona, there were many conversations about…

The Rise of the Next-Gen CDMO: Strategies for Reducing Risk and Time to Market

16 October 2024

By Alex Vasiev, Head of Biointerface, Springboard Creating and producing advanced drug-device combinations, like autoinjectors and pen injectors, requires a…

Does My Medical Device Design Actually Work?

6 August 2024

There are few experiences that can surpass the joy of seeing a product you developed reach manufacture. But before that,…

Best Practices Handling Material Changes For Medical Devices

26 March 2024

Medical device companies are heavily reliant on injection-molded plastic components, which might be produced either in-house or through a contract…

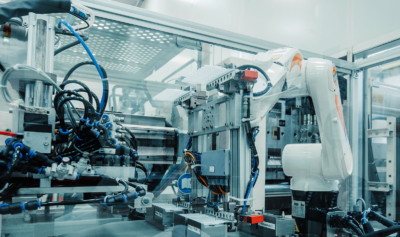

Lab-On-Chip Devices: Materials Considerations

18 March 2024

Material selection and testing can often be one of the critical challenges to developing microfluidic devices for the healthcare and…

Using 3D Resin Printers for Early Product Design

11 March 2024

Rapid Prototyping with 3D Printers Stereolithography (SLA) 3D printing can be a powerful tool when working on early-stage product design….

Design controls in medical device development: Ensuring safety and quality

20 June 2023

The development of medical devices is a complex and highly regulated process that requires meticulous attention to detail and a…

Transfer to manufacture: selecting a partner

1 February 2023

It is a nightmare scenario: you have a great product and commercial opportunity, but you are going to be late…

Top five tips for sustainable device design

10 October 2022

Following COP26, device manufacturers are facing increasing pressure both from government and from consumers to reduce the environmental impact of…