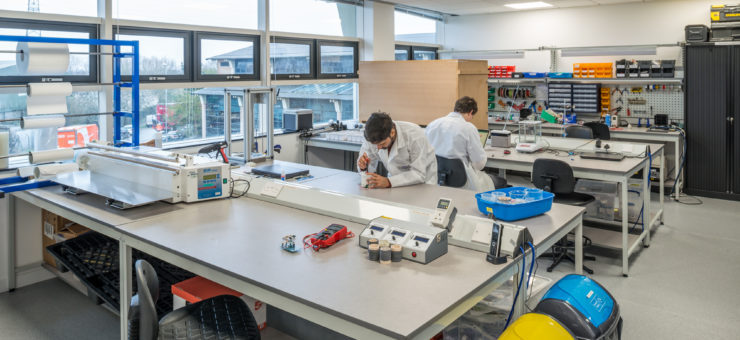

New expanded lab space at Springboard

10 July 2020

Work has recently been completed on Springboard’s new expanded lab space. Walls between the lab and the previous sub-let area were removed to create a larger lab and new flexible meeting space. The additional floor space in the lab has allowed us to increase specialised areas as well as adding more multi-purpose bench space.

Dedicated measurement area:

Our CMM, tensiometer and torque tester are regularly used on a wide range of projects from measuring device friction to inspecting manufactured parts. The new lab space has allowed us to create a dedicated measuring area set apart from the rest of the lab which will help to reduce background noise and protect fragile parts.

Expanded wet lab and ovens area:

The wet lab is essential to many of our projects for use with chemicals, temperature-controlled applications, fluids and more. The additional dedicated space combined with equipment such as our laminar flow hood and environment chambers allows us to expand our capabilities in interesting new areas such as biologics.

Multi-purpose project benches:

As our projects cover a wide range of different areas, lots of our lab space contains multi-use project benches. These are assigned to each lab-based project to give a space to set up equipment, assemble prototypes or anything else that an individual project needs. We have gained six new multi-purpose benches which allow current projects to spread out and increases the space available for upcoming projects.

Electronics:

A couple of recent Springboard projects have made regular use of our two electronics benches. This area has everything needed for soldering parts or measuring electronic parameters all within easy reach. It is also the starting place for most test rigs or prototypes that use motors or Arduinos.

Workshop:

Although the workshop has not been changed by the recent expansion it still remains an important part of the lab. The ability to make small changes to part quickly, e.g. drilling a hole to test vapour transmission or filing an edge during assembly, often saves projects time and expenses compared to outsourcing the task.

— Rachel Lewis